USAGE & PROCESSING INSTRUCTIONS

Content

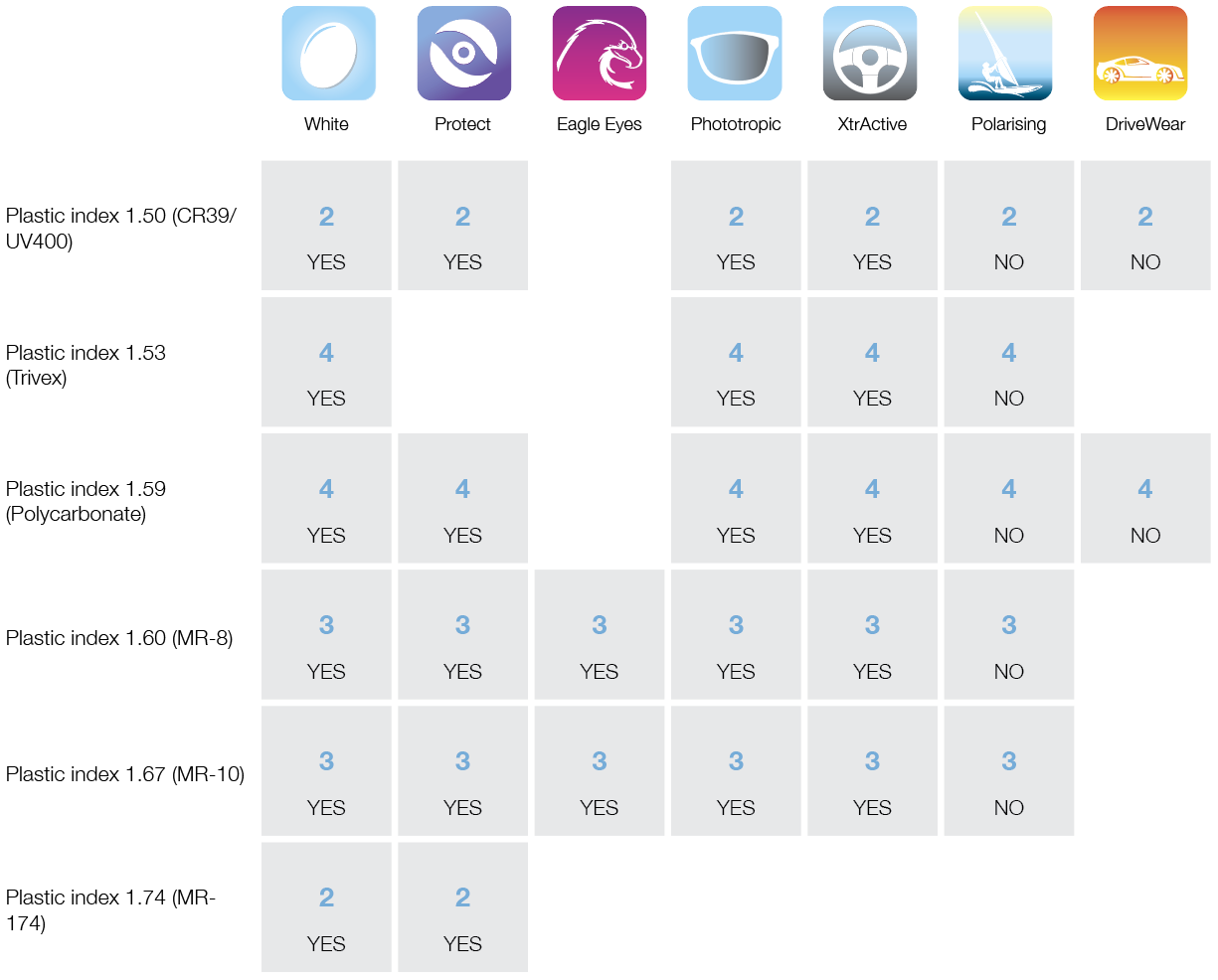

Lens materials: Plastic

Please check with the manufacturer of your sanding machine about the settings to be made separately for the processing of polycarbonate and trivex. For example, in traditional automatic machines with a grinding wheel, dry grinding is usually necessary.

Please pay particular attention to the care instructions on page 94 for polycarbonate.

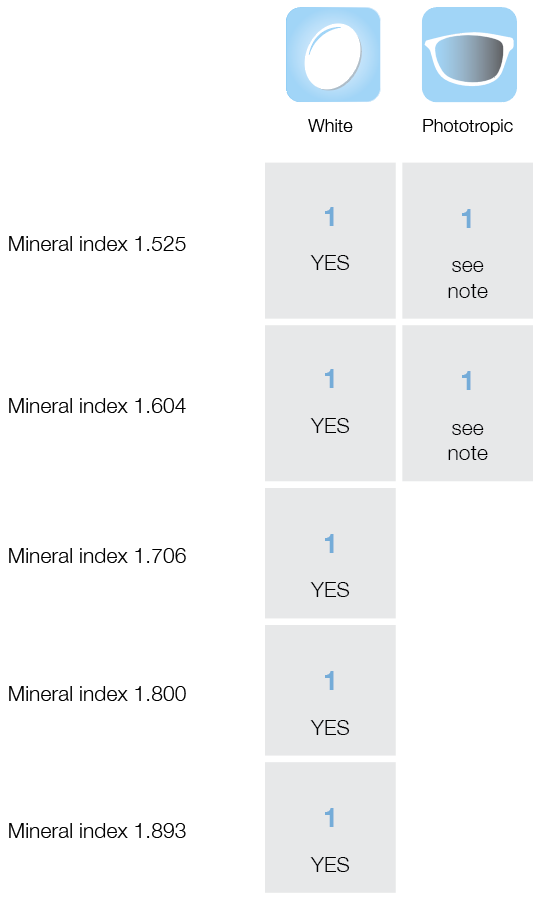

Lens materials: Mineral

Please also check with the manufacturer of your grinding machine about the settings to be made separately for the processing of mineral glasses.

Care instructions

Resistance to detergents

Plastic lenses are basically not acid-resistant. Cleaning should not be carried out with sharp cleaning agents, as this may result in peeling of the coatings or matting of the plastics. In the case of polycarbonate and Trivex, it is also essential to refrain from cleaning with acetone and ethanol. In general, it is recommended to clean the lenses and remove stamps with isopropyl alcohol.

The lenses should be thoroughly cleaned by the end user under lukewarm, running water with a drop of normal detergent. Microfibre spectacle cleaning cloths are ideal for cleaning on the go.

Resistance to thermal stress

Under no circumstances should plastic glasses be exposed to temperatures above 70°C. In particular, extended exposure to heating (e.g. sauna session) should be avoided, since due to the different coefficients of expansion of the material and coating, in addition to deformations, cracks in the coatings can also occur.

Depending on the type of glazing and shape (especially when glazing for tension in metal frames), the susceptibility to temperature can be further increased. The basic recommendation is therefore not to expose the incorporated lenses to temperatures above 55 ° C.

Lens designs

Reading glasses and office designs

Restrictions on use may arise due to the chosen glass design.

Lenses for working at close and intermediate ranges or at the computer workstation are not suitable for driving motor vehicles. These include, for example, classic reading glasses with close-range vision strength as well as office designs that do not provide a sufficiently large distance range that would allow safe participation in road traffic.

Multi-focal lenses

The use of bifocal and progressive lenses in road traffic is not subject to any restrictions. However, the functionality of multi-focal lenses depends on a sensible positioning in front of the eye, since it is not possible to see clearly in the distance at close range. Please note our centring recommendations.

Restrictions on use can also arise with custom-made products e. g. with:

- multi-focal lenses with a ground-in segment

- lenticular glasses for aphakic eyes

- cemented lenses

- multi-focal lenses with prismatic segment

- lenticular minus glasses

- biconcave glasses

In particular, reference should be made to lenticular glasses, which are conceptually constructed in such a way that they provide the actual visual acuity only in the centre of the lens. When adjusting, please note that significant blurring is to be expected in the area of the periphery. This can lead to field of vision restrictions, which can lead to a hazard, especially when participating in road traffic.

Breakability

Please note that our lenses are basically designed in such a way that they comply with the requirements of DIN / EN / ISO 14889 section 4.4 in terms of their mechanical strength.

We hereby expressly point out that they do not meet the requirements for safety glasses in the sense of EN166.

Finishings / coatings

Superhydrophobic coatings

Such coatings offer particularly smooth surfaces with the aim of generating a beading effect of water, etc. When processing these, it should be noted that Wetzlich works with a so-called anti-twist protection. This is applied as an additional layer and must be removed after processing with isopropyl alcohol.

Mirror coatings

In general, when combining mirror coatings with colours that deviate from the standard (e. g. Mirror Green to 75% blue glass coloration), it should be noted that both the “see-through colour” and the colour of the mirror can differ unpredictably from the expectation with such a composition. We do not categorically rule out such a combination in terms of production technology, but we cannot guarantee roadworthiness for a combination that has not been tested before and therefore recommend that roadworthiness be precautionary in such combinations, since signal colour distortions cannot be ruled out in particular.

Hard coats

All our coating packages include hard coats. When selling these, we expressly recommend that you do not use terms such as “scratch-resistant” or “scratch-resistant” in the sales conversation, so as not to arouse false expectations from the end consumer. The coatings used are state-of-the-art and lead to a correspondingly more scratch-resistant surface, but in no way claim to protect against every mechanical action.

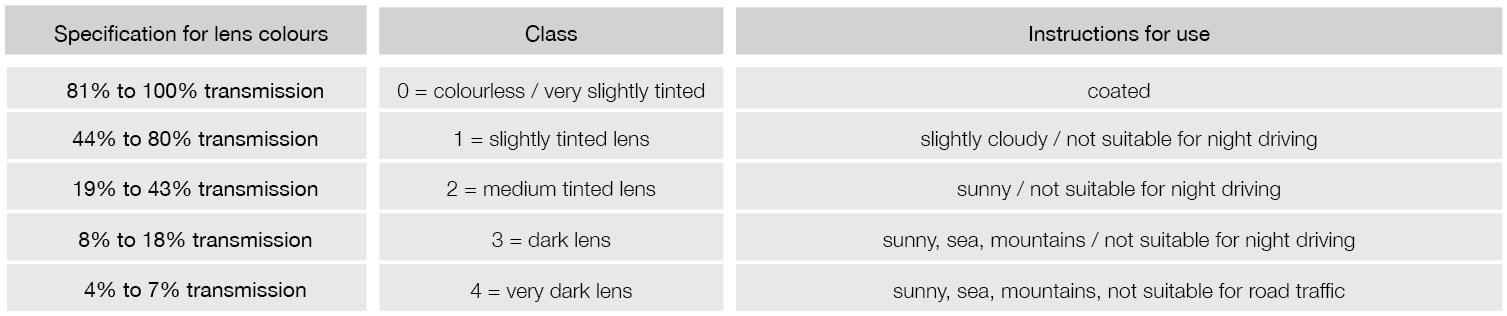

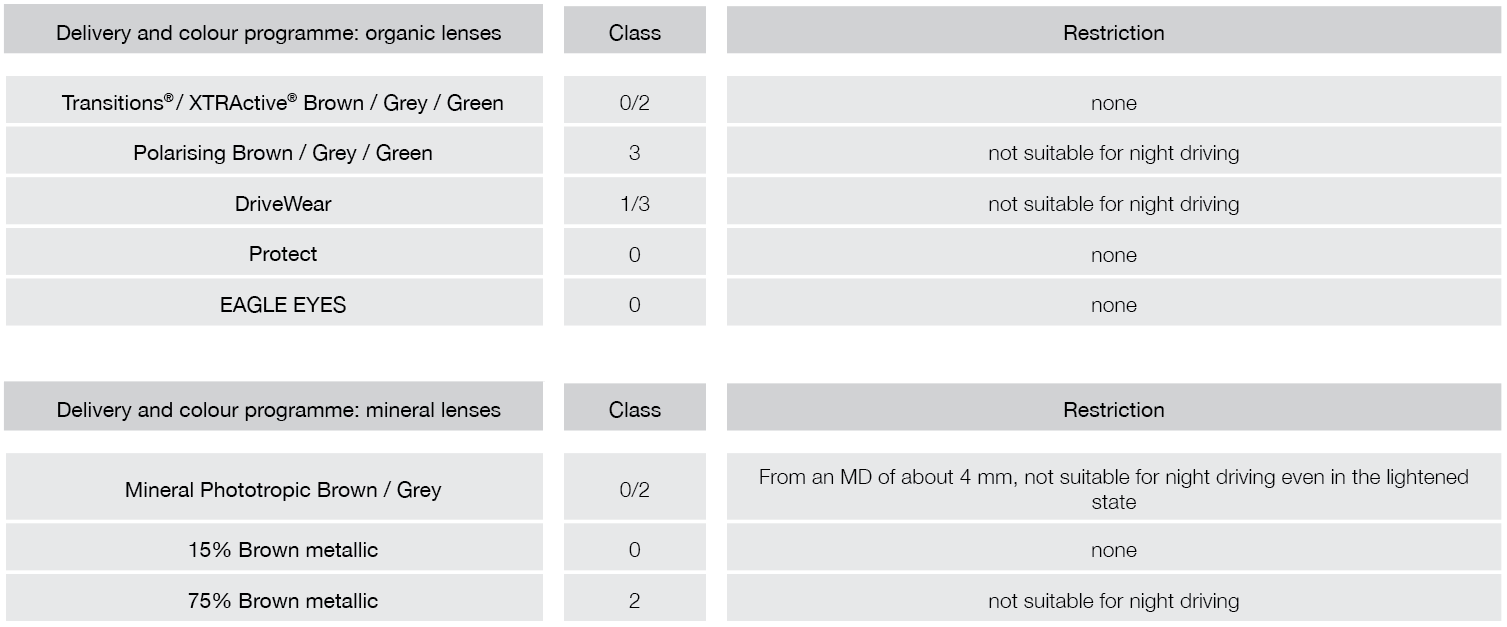

Colours

In the event that you decide to use tinted (coloured) lenses, then we refer you to the related categorisation into classes based on the chosen tint. The product thus complies with the European Directive 89 / 686 / EEC according to the standard EN ISO 12312-1:2015 (sunglasses for general use). In the case of the selected tint, the spectacle lens corresponds to the following class and, as a result, comes with a corresponding restriction of use. The absorption specification refers to the darkest area of the lens. In the geometric centre of the lens, the protection level / -class can differ from that of the darkest lens area.

Lenses are not suitable for driving if:

- tinted lenses do not allow signal recognition (e. g. in the case BlueBlocker colours)

- the transmittance is below 8%

- lenses are not suitable for night driving if:

- the transmission is less than 75%.

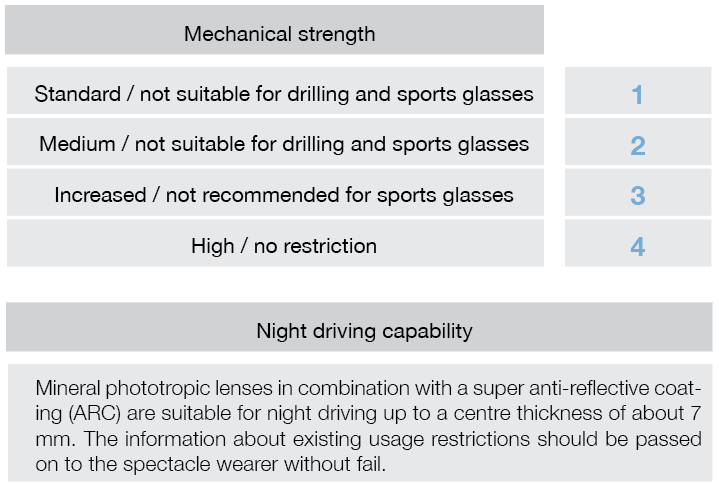

Technologies

Additional properties of spectacle lenses can also lead to restrictions in use, owing to the fact that they change the transmission properties of visible light, such as in the case of phototropic lenses and blue light protection.

Phototropic mineral lenses are suitable for night driving non-anti-reflective if the centre thickness is up to about 4mm. With anti-reflective coating, a night driving capability up to a centre thickness of about 7 mm is guaranteed. Beyond the mentioned centre thicknesses, these types of lens are not suitable for night driving.

The data of the protection levels / classes for phototropic lenses refer to measurements after 24 hours of storage of the lens in the dark at 25 ° C for the lightened state; for the darkened state, the data of the measurements refer to one hour of irradiation in full sunlight (laboratory simulation).

In practice, greater absorptions occur at lower temperatures than at higher temperatures and “cloudy” weather. This fact does not limit the assessment of roadworthiness, but can lead to the fact that a protection level limit may be exceeded in the darkened state. In the case of mineral phototropic lenses coloured in bulk, this effect can also be enhanced by larger centre thicknesses. From the specified borderline centre thicknesses, the lenses are to be regarded as not suitable for night driving even in the lightened state.

The information about existing usage restrictions should be passed on to the spectacle wearer without fail.

Fitting and centring

Workshop notes

Single-vision lenses

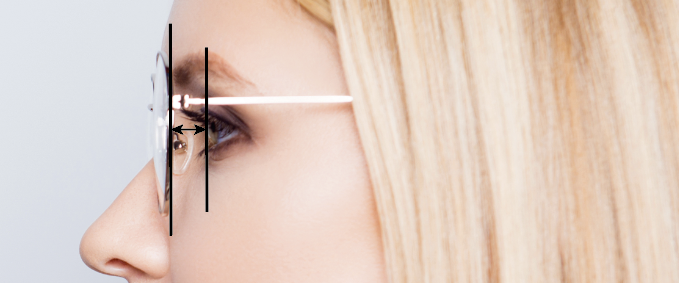

The Fitting takes place according to the Main viewing line. To do this, ask your client to slightly shift the head to the back of the neck until the frame is perpendicular to the floor and mark the pupil centre.

Support for close-range vision / young presbyope

The Fitting is carried out according to zero gaze direction. Ask your customer to maintain a normal head and body posture and mark the viewing point (pupil centre) on the lens.

Progressive lenses

The Fitting is carried out according to zero gaze direction. Ask your customer to maintain a normal head and body posture and mark the viewing point (pupil centre) on the lens.

FreeForm Bifocal lenses

The Fitting is carried out according to zero gaze direction. Ask your customer to maintain a normal head and body posture and mark the viewing point (pupil centre) on the lens.

Office lenses

Depending on the design, our room and PC lenses are adjusted either by the main viewing line (Main viewing line for aspheric single-vision lenses) or by the zero gaze direction. Order according to close-range value with indication of degression.

Workshop ordering information

- All orders are generally processed according to box size

- The order is made according to far-PD

- Single-vision lenses are incorporated to the specified PD and height. If no height is specified, grinding takes place according to the geometric centre

- Aspherical lenses are also incorporated according to far-PD with the specified height. Please note the compliance with the Main viewing line

- Reading glasses are ground according to the specified PD – we do not make an independent conversion to a near-PD

- Please also order bifo and trifo glasses according to far-PD. The conversion to near-PD (-2.50 mm) is carried out automatically

Individual parameters

Some of our products can be ordered with additional individual parameters. In particular, in the event that no high-tech centring system is currently available, the collection of these always represents an additional difficulty. It is tempting to prefer to order with the standard parameters, and the product thus loses quality. With the following small guide, we would like to make collecting the parameters as unproblematic as possible for you:

1. RVD

If you do not specify a RVD when ordering, we generally assume a standard RVD of 14 mm. Certainly, in the case of the RVD, it does not depend on the second place after the comma, since it is constantly changing by the normal movement of the glasses alone. However, it is important here to inform us of extreme deviations. E.g.: At 3.00 dpt, the refraction between a RVD of 14 mm and 20 mm changes by only 0.05 dpt. At 10.00 dpt, it is already 0.57 dpt. It is definitely better to work with an inaccurately measured RVD rather than the standard RVD.

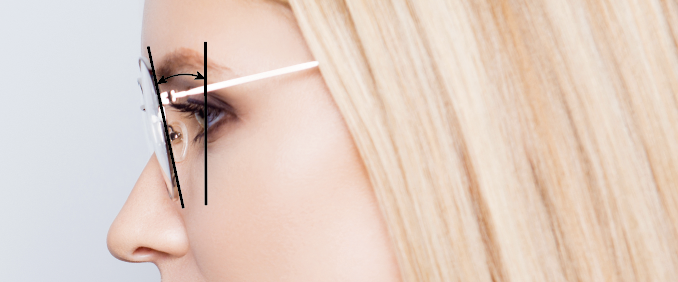

2. Angle of inclination

This also applies in particular to sports glasses: Better measured with a small inaccuracy than not at all. If not specified, we assume a standard pantoscopic tilt of 7 degrees. If no other measuring device is available, simply determine the deviation of the angle between the front of the socket and the bracket to 90 degrees.

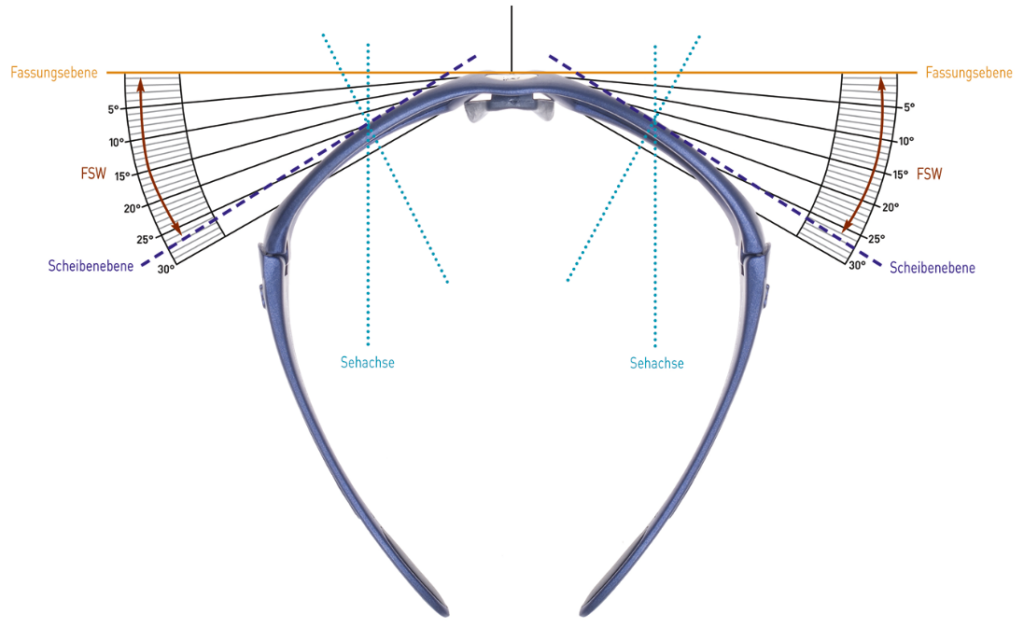

3. Face form angle

Simply place the frame on the graphic below and use a ruler to determine the angle. Unless otherwise stated, we assume a standard of 5 degrees for correction versions.

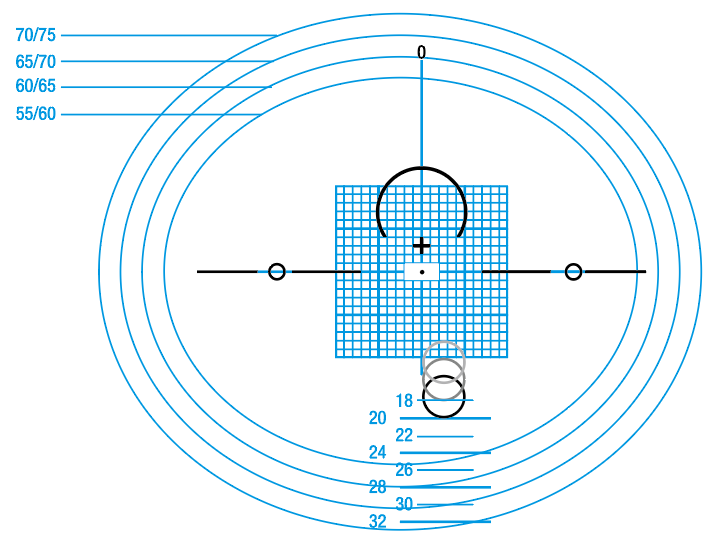

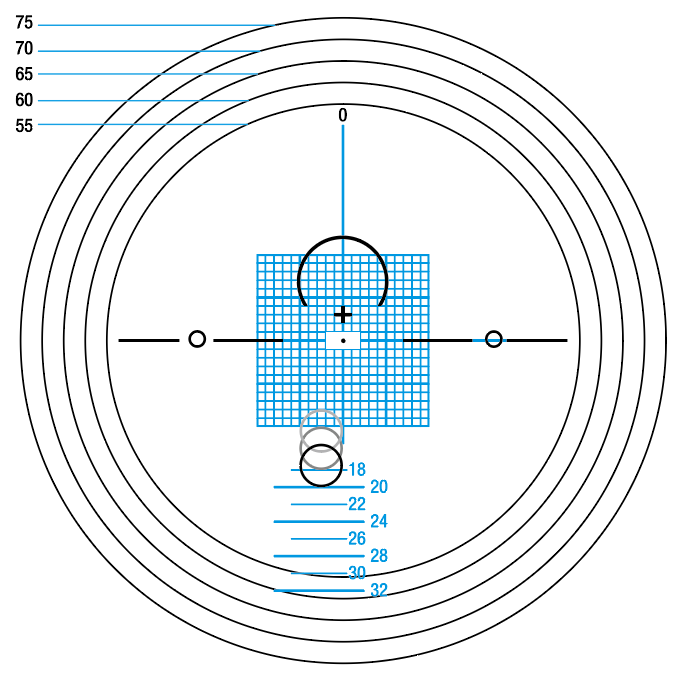

Diameter – round or elliptical?

In general, the following applies: If a lens is ordered, for example, 70/75 de-centrally, this does not mean that it will also be delivered elliptically – not even with high plus values. Of course, depending on the axis position, this automatism is quite reasonable for plus lenses in terms of mass, since it can thus significantly save on thickness – however, the variety of available frames means that automatism can also lead to the fact that you will not be supplied with sufficiently large lenses.

Unless otherwise stated, we assume that you want round lenses.

On request, you can also get any of our lenses elliptical at no extra charge. Elliptical lenses are particularly useful for medium and high additions as well as astigmatic corrections with axis positions of 0 / 180 degrees (+/- 30 degrees in the plus cylinder). Example: sph +4.00 / cyl +2.00 / A0 / ADD 2.50. Please note that all of our elliptical stencils are shown in a decentralised manner.

If you order via tracer, all information on diameter and decentration will be overwritten by us and an optimal product will be manufactured. Optimal means here that it is determined both whether the oval variant brings a gain in terms of thickness and that we make an optimal decentration. This can also be done completely differently to the order standards with 2.5 mm or 5 mm decentration (70 / 75 or 70 / 80), so that you would get, for example, 62 / 74. This selection is made fully automatically.

Please also note that warehouse lenses and Weviline Basic products are excluded from automatic decentration and diameter Fitting.

Do you have any questions?

About Wetzlich

We have been manufacturing lenses with the highest precision and innovative strength in Germany at our site on the Lower Rhine area since 1935.

We not only ensure that you simply see better and more with our products. For years, we have been developing lenses that provide optimum protection for your eyes. This includes, for example, our UV and infrared protection coating as well as innovative lens materials that filter blue light and increase contrast.

With one of the most modern European machine parks, we stand for advanced products with the highest quality standards at fair prices.

You can obtain Wetzlich lenses from your optician. Simply ask him about our lenses or find a Wetzlich partner optician in our optician search.